by Nathan Pharaoh on 27 March, 2015

Shortly after the installation of the engine’s crankshaft, the team here at the National Museum got busy bolting on the auxiliary engine components with the aim of reuniting the vehicle’s engine to the newly treated chassis.

But before the engine is installed, we need to carry out a few leak tests and pressure tests.

For the non-mechanically minded, the Daimler is fitted with a mechanical lubrication system. A mechanical pump is activated by the spinning of the crankshaft and pressurises the oil channels. In basic terms, as the engine spins, oil is pumped throughout the internal workings. This reduces friction and corrosion and ensures that the engine runs smoothly and reliably.

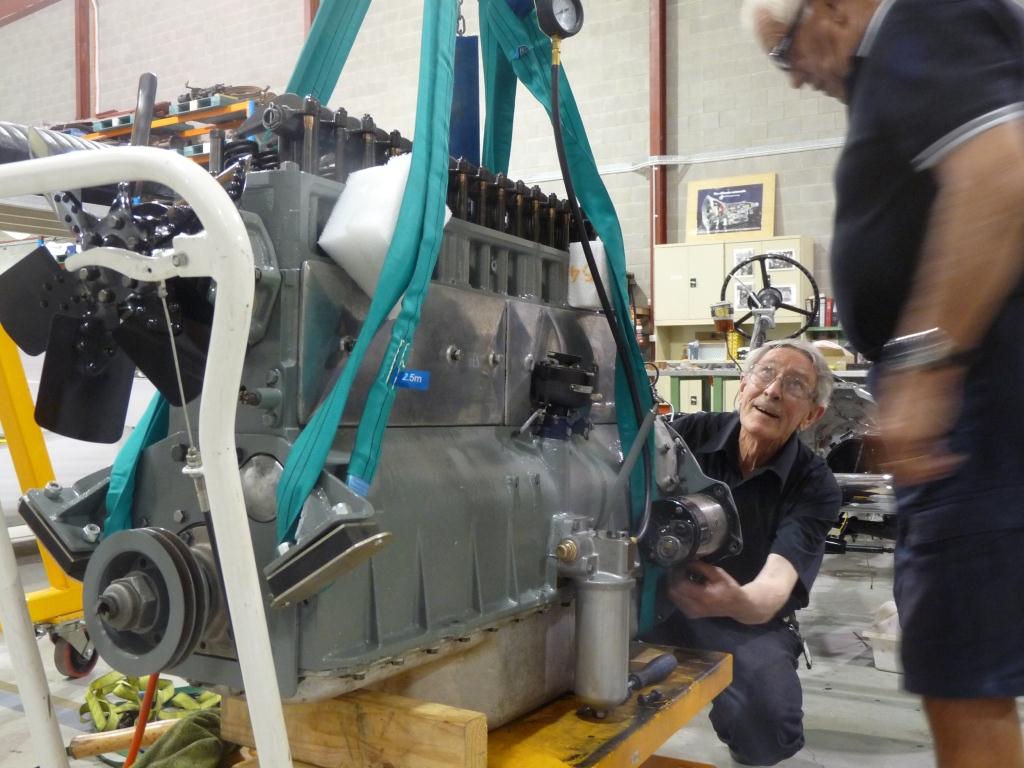

By engaging the vehicle’s starter motor, Ian and Ken were able to rotate the engine at speed, activating the oil pump and in turn pressurising the system. This oil “pressure test” also gives the team the opportunity to see the valve train in motion. After seeing the chassis and engine in so many pieces, this test was quite a milestone and the Museum’s conservators gathered to watch – as result the test was repeated about 6 times.

Here is a link to the video: Oil Pressure test

After the successful testing of the lubrication system, we are now set to install the engine into the chassis.

As the newest member of the team, I am really looking forward to posting more information and meeting some of the extended Royal Daimler community in the not too distant future.