by Nathan Pharaoh on 7 October, 2016

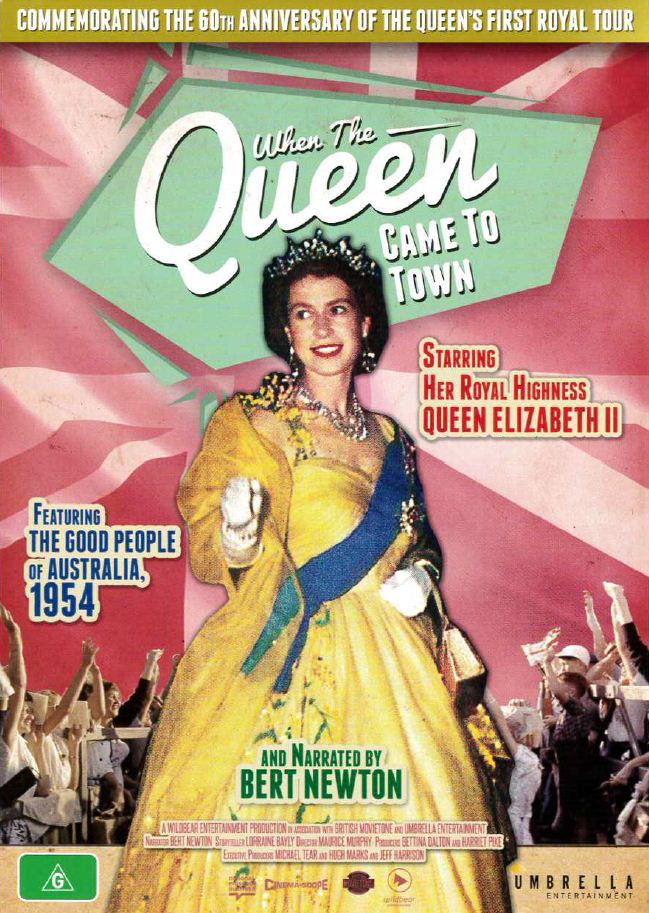

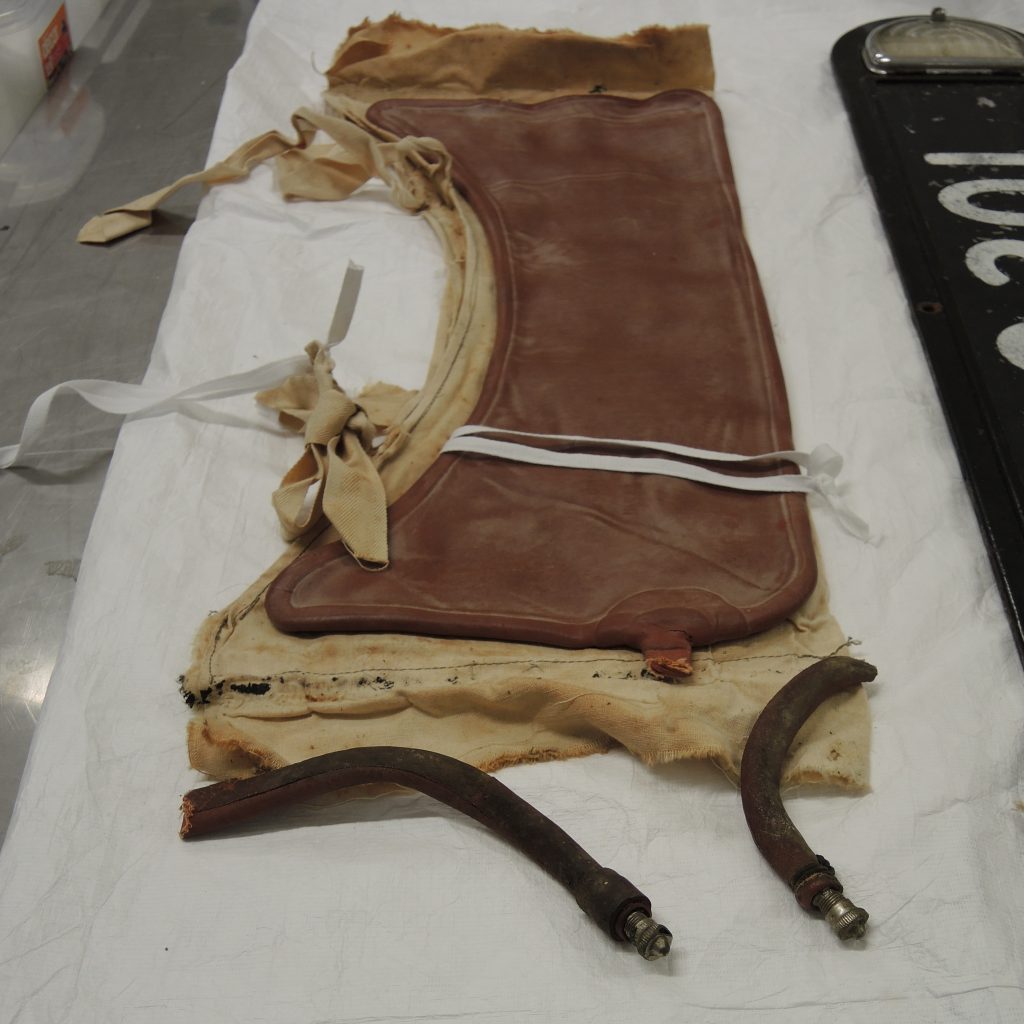

This strange looking object is an adjustable air-bladder lumbar support which would have provided a comfortable ride for Queen Elizabeth II during her 1954 tour of Australia.

Continue reading “Look what we found!”